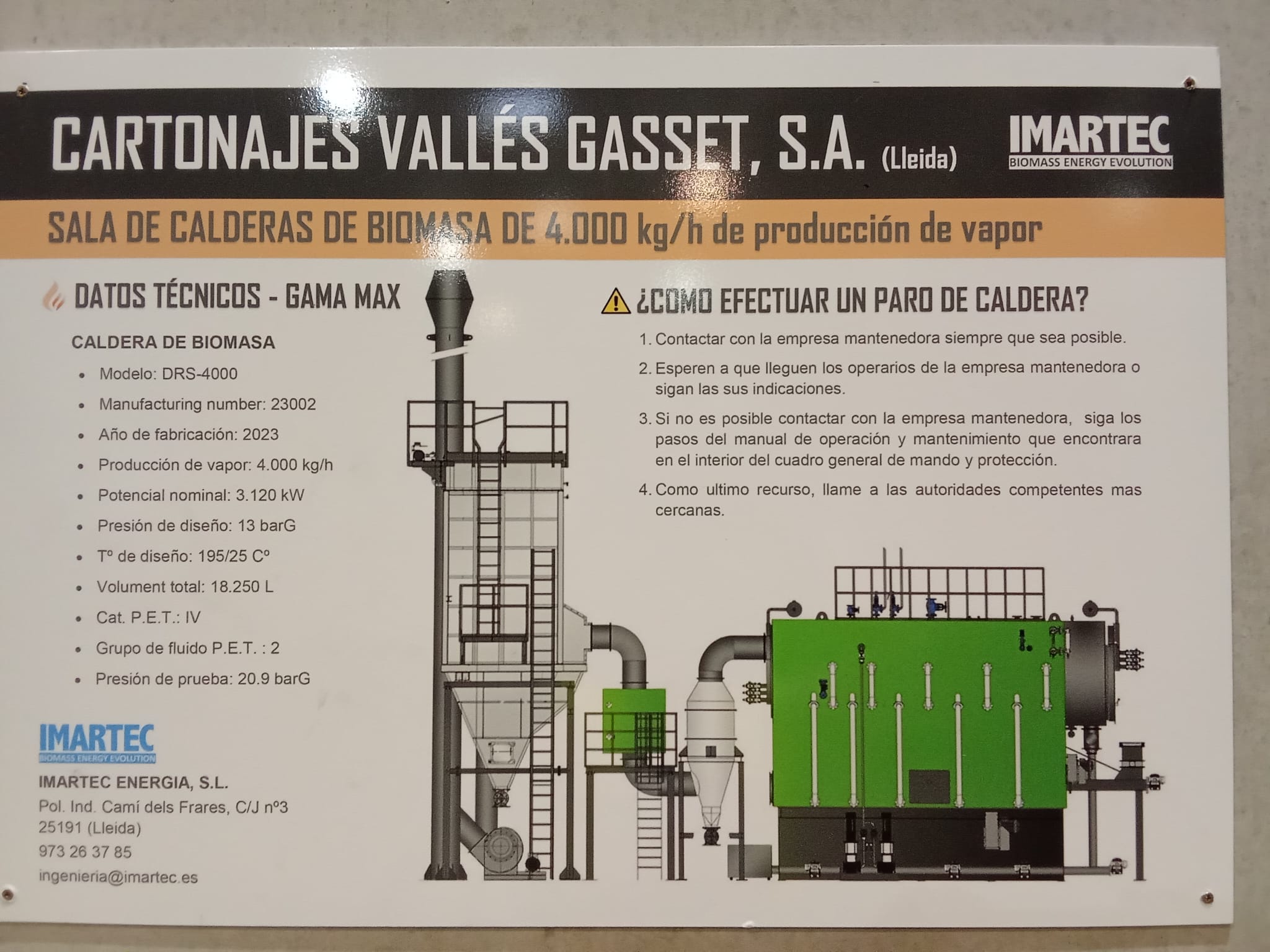

Biomass plant installation

Steel boiler with four flues mod. GLOBAL/G/V of 2,800 kW of useful thermal power for the production of 4,000kg/h of steam at the working pressure from 8bar to guarantee the CONTINUOUS availability of 8,000 hours of non-stop service, equipped with a suitable base for the installation of the mechanical feeder with DUPLO technology to serve a home with

INCLINED MOBILE GRILL

The boiler has been studied and made to use solid woody and similar materials as fuels, alternatively liquid and gaseous fuels. The self-supporting structure of horizontal development is manufactured in thick sheet steel, thickness min. 10 – max. 12 mm, suitable for supporting functional thrust pressures through specific traction bars. The combustion chamber has several smoke circuits for the optimal decantation of the powders contained in the smoke, with variable internal temperatures of 900/1,300°C, and has doors for periodic cleaning. In addition, it incorporates a post-combustion chamber with high-speed gas entry in turbulent form, generated by the special secondary combustion air injection system. The refractory coating, of ideal thickness and characteristics, differentiated in the various zones, guarantees the maintenance of temperatures for optimal combustion and for the protection of the load structures.

Project and installation by company